Product Description

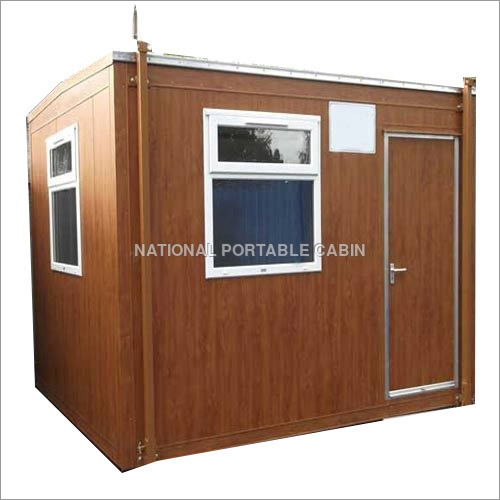

Portable Cabin for Airports is a prefabricated structure with good storage capacity that make it highly demanding and popular among our customers. The structural frame of this modular unit is fabricated by using top-quality aluminium and various engineering materials that makes it sturdy and robust enough to bear extreme outdoor conditions. It is also mounted with a lightening arrester to protect accidents during thunderstorm. Portable Cabin for Airports designed by us can be customized into various sizes as per customer demands.

Product details

| Built Type | Modular, Prefab |

| Material | Aluminum |

| Feature | Eco Friendly, Easily Assembled |

| Use | Kiosk, House, Shop |

Reliable Safety with Fire Retardant PanelsThe Class B1 fire rating and high-quality fire retardant panels secure these cabins against risks, making them suitable for high-traffic airport zones. Polyurethane/EPS/PIR insulated sandwich panels enhance protection while ensuring energy efficiency and comfort.

Built for Harsh Conditions and MobilityResistant to wind speeds of 150 km/h and earthquakes in zone IV & V, each cabin is designed for demanding environments. Integral lifting hooks and skid-mounted structures allow effortless relocation at airports or other sites, without requiring a foundation.

Ready-to-Use ConvenienceThe cabins are equipped with ISI certified pre-wired electrical systems, LED tube/panel lights, and air conditioning provisions. Assembly is quick, completed within 4-6 hours, and standardized or customizable sizes ensure adaptability to various airport requirements.

FAQ's of Portable Cabin for Airports:

Q: How is the fire safety of these portable cabins ensured at airports?

A: The portable cabins use Class B1 fire-rated panels and fire retardant materials, with polyurethane/EPS/PIR insulation. These features provide high-level fire resistance suitable for airport environments, ensuring occupant safety and compliance with strict standards.

Q: What is the process for relocating these airport cabins, and where can they be positioned?

A: Relocation is simple due to integral lifting hooks and the skid-mounted base, allowing the cabins to be repositioned with lifting equipment. They don't require a foundation and can be placed in various airport zones, including security, office, or lounge areas.

Q: When can the portable cabins be assembled and made operational?

A: The cabins are designed for rapid deployment, with assembly typically completed within 4-6 hours after delivery. Pre-wired electrical fittings and modular bolted connections further accelerate installation, ensuring quick operational readiness.

Q: What are the usage benefits for airports opting for these cabins?

A: Airports benefit from modularity, durability (life span of 15-20 years), fire and weather resistance, flexibility in size and internal layouts, and 100% leak-proof roofing. The cabins provide ready-to-use spaces for temporary offices, lounges, or security posts with superior comfort.

Q: How do the construction features support harsh weather and earthquake conditions?

A: The cabins are built with galvanized steel framework, corrugated steel roofs, and insulated pre-coated sandwich walls, offering wind load resistance up to 150 km/h and earthquake tolerance up to zone V. This ensures stability and safety for airport operations even in extreme conditions.

Q: What internal and external finishes do these cabins offer for airport environments?

A: Externally, the cabins are painted with UV-resistant coatings to withstand outdoor exposure. Internally, they feature laminated boards or pre-painted surfaces, providing a clean and modern appearance that suits any airport usage scenario.

Q: Can the cabin dimensions and color be customized for specific airport needs?

A: Yes, the cabins are available in standard sizes (20ft x 10ft x 8.5ft) or can be customized to other dimensions. The color options include white, grey, or other finishes as requested, allowing airports to match branding or site requirements.